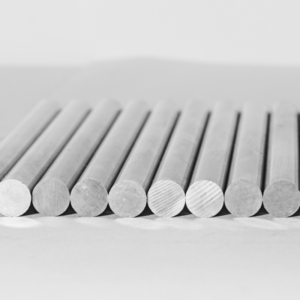

Carbide rods for drilling have revolutionized the way drilling operations are conducted across various industries. Their exceptional hardness, durability, and versatility make them indispensable tools for achieving precision and efficiency in drilling tasks. In this article, we will delve into the numerous advantages of using carbide rods for drilling and how they contribute to enhanced productivity and performance.

Carbide rods for drilling are engineered from a combination of tungsten carbide and cobalt, resulting in a material renowned for its exceptional hardness and wear resistance. This unique composition enables carbide rods to withstand the high temperatures and abrasive forces encountered during drilling operations, making them ideal for a wide range of applications.

One of the primary advantages of using carbide rods for drilling is their remarkable durability. Unlike traditional drill materials such as high-speed steel, carbide rods maintain their cutting edge sharpness for an extended period, minimizing the need for frequent tool changes and downtime. This durability translates to increased productivity and cost savings for businesses, as fewer replacement tools are required to complete drilling tasks.

Additionally, carbide rods exhibit superior hardness compared to other drill materials, allowing them to penetrate tough materials with ease. Whether drilling through metal, wood, or composites, carbide rods deliver consistent and precise results, ensuring smooth and accurate boreholes every time. This level of precision is essential in industries where dimensional accuracy is critical, such as aerospace, automotive, and manufacturing.

Another significant advantage of carbide rods for drilling is their excellent thermal conductivity. This property enables them to dissipate heat efficiently during drilling, reducing the risk of overheating and prolonging tool life. As a result, carbide rods can withstand prolonged use in high-speed drilling applications without experiencing thermal degradation, maintaining their cutting performance even under demanding operating conditions.

Furthermore, carbide rods offer versatility in drilling operations, allowing for the creation of a wide range of hole sizes and shapes. Whether drilling pilot holes, counterbores, or chamfers, carbide rods can be tailored to meet specific application requirements, providing flexibility and adaptability in manufacturing processes. This versatility makes carbide rods suitable for various industries, including construction, mining, oil and gas, and metal fabrication.

The use of carbide rods for drilling also contributes to improved surface finish and hole quality. Their sharp cutting edges and precise geometry result in clean and burr-free bores, minimizing the need for secondary finishing operations. This not only saves time and labor but also ensures the integrity of the final product, enhancing overall quality and customer satisfaction.

Moreover, carbide rods are compatible with a wide range of drilling equipment, including handheld drills, drill presses, and CNC machining centers. Their compatibility with different drilling platforms makes carbide rods accessible to manufacturers of all sizes, from small-scale workshops to large-scale production facilities. This accessibility democratizes access to advanced drilling technology, empowering businesses to optimize their drilling processes for maximum efficiency and profitability.

In conclusion, the advantages of using carbide rods for drilling are undeniable. Their exceptional hardness, durability, thermal conductivity, and versatility make them indispensable tools for achieving precision and efficiency in drilling operations. By leveraging the benefits of carbide rods, businesses can enhance productivity, improve quality, and gain a competitive edge in today’s demanding marketplace. Whether drilling through metal, wood, or composite materials, carbide rods offer a reliable and cost-effective solution for achieving superior results in drilling applications.