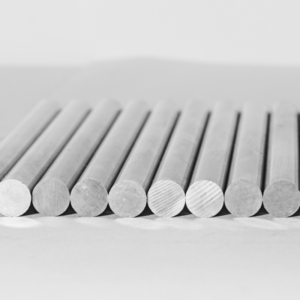

Carbide rods stand as stalwarts in the realm of metalworking industries, embodying a fusion of strength, durability, and precision. As essential components in cutting tools and machining applications, carbide rods revolutionize metal fabrication processes, offering a myriad of advantages that elevate productivity and efficiency to unprecedented heights.

At the core of carbide rods lies tungsten carbide, a compound renowned for its exceptional hardness and heat resistance. This amalgamation of tungsten and carbon imbues carbide rods with unparalleled durability, rendering them capable of withstanding the most rigorous machining conditions. With a hardness surpassing that of steel, carbide rods exhibit remarkable resistance to wear, ensuring prolonged tool life and reduced downtime.

The advantages of carbide rods manifest prominently in their superior cutting performance. Whether in milling, drilling, or turning operations, carbide rods deliver precision cuts with pristine surface finishes. Their inherent hardness allows for higher cutting speeds and feeds, resulting in enhanced material removal rates and heightened productivity. Additionally, carbide rods maintain sharp cutting edges over prolonged periods, minimizing the need for frequent tool replacements and optimizing machining efficiency.

In the landscape of metalworking industries, where precision is paramount, carbide rods reign supreme. Their inherent rigidity and stability enable the attainment of tight tolerances and intricate geometries with utmost accuracy. This precision translates into superior part quality and dimensional consistency, meeting the stringent requirements of modern manufacturing processes.

Furthermore, carbide rods offer versatility across a spectrum of materials, from steels and alloys to composites and ceramics. Their exceptional thermal conductivity and resistance to thermal deformation facilitate efficient chip evacuation and dissipation of heat during cutting operations. This capability not only prevents tool overheating but also ensures prolonged tool life, even in high-temperature machining environments.

One of the distinguishing features of carbide rods is their adaptability to diverse machining applications. Whether in heavy-duty roughing or fine finishing, carbide rods exhibit consistent performance across a breadth of cutting conditions. Their ability to withstand both high-speed and high-feed machining strategies underscores their suitability for a wide range of metalworking processes.

Moreover, carbide rods contribute to sustainable manufacturing practices by reducing material waste and energy consumption. Their extended tool life and superior cutting efficiency translate into reduced resource consumption and minimized environmental impact. By optimizing machining processes and enhancing productivity, carbide rods pave the way for greener and more efficient metalworking operations.

In conclusion, the advantages of carbide rods in metalworking industries are unequivocal. From their unmatched hardness and durability to their precision cutting capabilities and versatility, carbide rods stand as indispensable assets in modern manufacturing. As the cornerstone of cutting-edge machining technologies, carbide rods propel metalworking industries toward greater efficiency, accuracy, and sustainability, ushering in an era of unprecedented innovation and progress.